| Executive Standard | Grade / Material |

|---|---|

| ASTM A53 | A, B |

| ASTM A179 | Low Carbon Steel |

| ASTM A106 | A, B |

| ASTM A213 | T5, T11, T12, T22 TP 347H |

| ASTM A192 | Low Carbon Steel |

| ASTM A210 | A1, C |

| ASTM A333 | Gr.6 |

| ASTM A312 | TP304/304L, TP316/316L |

| ASTM A519 | 4130,4140 |

| ASTM A335 | P9, P11, P22 |

| ASTM A789 |

Cold Drawn Seamless Pipe are available in wide Range of Thickness

| Designation of Diameter | Nominal Wall Thickness | ||||||

|---|---|---|---|---|---|---|---|

| SCH.5 | SCH.20S | SCH 10S | SCH.40S | ||||

| Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | |

| 20 | 1.65 | 1.03 | 2.5 | 1.49 | 1.3 | 2.87 | 1.71 |

| 10 | 2 | 0.74 | 0.63 | 2.31 | 0.87 | ||

| 40 | 1.65 | 1.93 | 3 | 3.35 | 3.16 | 3.68 | 4.11 |

| 50 | 1.65 | 2.42 | 3.5 | 4.9 | 3.99 | 3.91 | 5.52 |

| 100 | 2.11 | 5.93 | 4.5 | 12.18 | 8.5 | 6.02 | 6.32 |

| 80 | 2.11 | 4.59 | 4 | 8.37 | 6.56 | 5.49 | 11.47 |

Providing Inspection and Testing Facilities Such as

- Ultrasonic testing

- Dye Penetrant Inspection

- Magnetic Particle Inspection:

- Non-destructive Testing

- X-ray

- Flattening test

- Eddy Current Testing

- Hydraulic test

- Flaring test

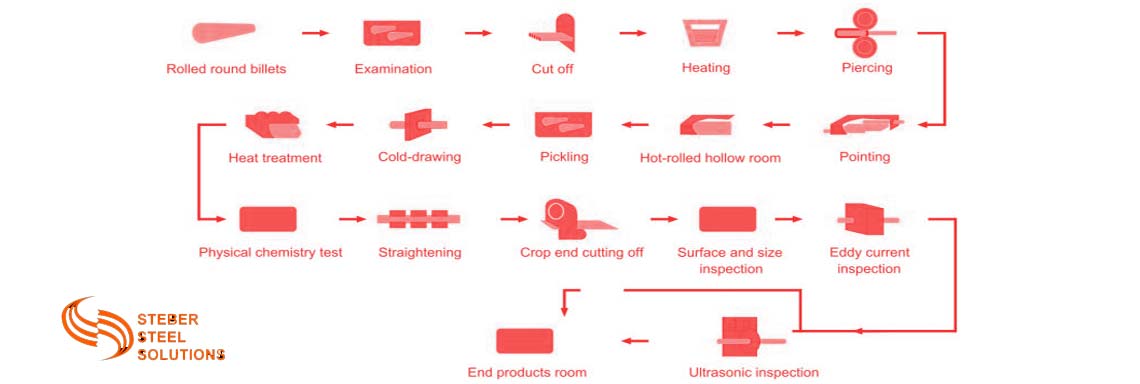

Check Manufacturing Process of Hot Finished Seamless Pipe

Why Choose US ?

- Weekly Delivery to Middle East Countries

- Get Quote Within 4 Hours

- Saudi Aramco Approved Material

- Odd Sizes Can be arranged within 3 Days

- 100% Tested and 0.5% Rejection Rate

- Supply Material With MTC EN 10204 / 3.1B

- Guaranteed 10% to 15% Lower Price As Compared to Other Suppliers

Manufacturer of SMLS Pipe according to DIN / EN Standard

| Executive Standard | Grade / Material |

|---|---|

| DIN 2391/EN10305-1 | St35, St45, St52 |

| DN 17175/EN10216-2 | ST35, ST45, ST52, 13CrMo44 |

| DIN 1629/EN10216-1 | St37, St45, St52 |

CDS Pipe in Cut to Length Sizes

| OD/THK | 3.25 | 6 | 2.95 | 2.34 | 4.06 | 2.64 | 1.63 | 1.85 | 1 | 1.42 |

|---|---|---|---|---|---|---|---|---|---|---|

| 41.28 | 3.048 | - | 2.789 | 2.247 | 3.727 | 2.516 | 1.594 | 1.799 | 0.993 | 1.396 |

| 28.58 | - | - | 1.865 | 1.422 | - | 1.689 | 1.083 | 1.220 | 0.680 | 0.951 |

| 57.15 | 4.320 | - | 3.943 | 3.163 | 5.316 | 3.549 | 2.232 | 2.523 | - | - |

| 44.45 | 3.302 | - | 3.019 | 2.430 | 4.044 | 2.722 | 1.721 | 1.944 | 1.072 | 1.507 |

| 31.75 | 2.284 | - | 2.095 | 1.697 | - | 1.895 | 1.211 | 1.364 | 0.758 | 1.062 |

| 33.7 | 2.441 | - | 2.237 | 1.810 | - | 2.022 | 1.289 | 1.453 | 0.806 | 1.130 |

| 34.93 | 2.541 | - | 2.328 | 1.882 | - | 2.104 | 1.339 | 1.510 | 0.837 | 1.174 |

| 50.8 | 3.811 | - | 3.481 | 2.797 | 4.680 | 3.136 | 1.977 | 2.233 | 1.228 | 1.729 |

| 38.1 | 2.793 | - | 2.557 | 2.064 | 3.408 | 2.309 | 1.466 | 1.654 | 0.915 | 1.285 |

| 60.3 | 4.573 | - | 4.172 | 3.345 | 5.631 | 3.754 | 2.358 | 2.667 | - | - |

| 40 | 2.946 | - | 2.695 | 2.173 | 3.599 | 2.432 | 1.542 | 1.741 | 0.962 | 1.351 |

| 101.3 | 7.883 | 14.146 | 7.177 | 5.728 | 9.766 | 6.443 | 4.019 | 4.551 | - | - |

| 82.5 | 6.352 | 11.320 | 5.787 | 4.626 | 7.854 | 5.199 | 3.251 | 3.680 | - | - |

| 63.5 | 4.829 | 8.508 | 4.405 | 3.529 | 5.951 | 3.962 | 2.487 | 2.813 | - | - |

| 88.9 | 6.865 | 12.267 | 6.253 | 4.995 | 8.495 | 5.616 | 3.508 | 3.972 | - | - |

| 114.3 | 8.901 | 16.025 | 8.101 | 6.461 | 11.038 | 7.270 | 4.529 | 5.130 | - | - |

| 69.85 | 5.338 | 9.448 | 4.867 | 3.896 | 6.587 | 3.376 | 2.742 | 3.102 | - | - |

| 65 | 4.949 | - | 4.514 | 3.616 | 6.102 | 4.060 | 2.547 | 2.881 | - | - |

| 81.2 | 6.248 | 11.127 | 5.693 | 4.551 | 7.724 | 5.115 | 3.199 | 3.620 | - | - |

| 76.2 | 5.847 | 10.387 | 5.329 | 4.262 | 7.223 | 4.789 | 2.998 | 3.392 | - | - |

Exporter of Seamless Schedule 80 Pipe are widely used in high-pressure, low-temperature enviroment

- Construction

- Turbine Components

- Oil and Gas

- Automotive

- Power Generation

- Chemical Processing

- Agriculture

- Infrastructure

- Automotive & Transportation

API Standard Seamless Steel Pipes

| Executive Standard | Grade / Material |

|---|---|

| API Spec 5L PSL1 / PSL2 | A,B X46,X42,X56 , X52,X65 , X60, X70 |

| API Spec 5CT | J55, C90, K55, N80, L80,C95,P110 , T95, M65 |